What Is Saddle Stitch Binding?

Saddle stitching can be practical, classy and inexpensive.

Although it sounds like how a cowboy keeps his gear from falling apart, it is actually a very popular method of binding magazines and brochures. Let's see what we mean by "saddle stitch binding".

What is saddle stitch binding?

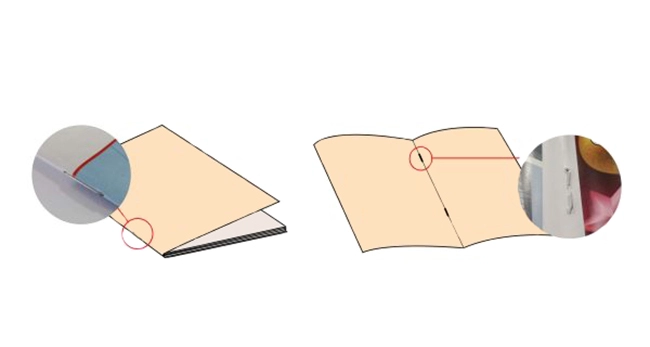

Depending on the material and number of pages, the spine of a saddle stitch bound magazine or booklet is bound with staples or wire. Lower-page booklets are usually bound with staples, which pass through the spine fold of larger printed materials. For higher-page magazines, catalogues or booklets, stacks of printed material are folded and fed into a metal saddle device where they are sewn together with metal wire. Once bound, the other three edges are trimmed to match the uniformity of the spine.

When is saddle stitch binding best?

Different materials require different binding techniques. Paperbacks or manuals with a large number of pages are best bound using perfect binding - a style of binding where the pages are joined together with strong, flexible hot glue and the pages are trimmed evenly. Saddle-stitch binding, however, is best reserved for magazine-style material, catalogues, and booklets. Saddle-stitch binding is also a very fast process compared to most other binding techniques, allowing for faster turnaround times.

Pros and Cons of Saddle Stitching

Pros:

Cheap: Saddle stitching is one of the cheapest binding options for booklet material.

Lay flat: Unlike perfect binding, saddle stitched documents are easy to lay flat and open.

Quick to produce: The turnaround time for producing saddle stitched material is very quick as there is no glue heating and drying process involved.

Disadvantages:

Not strong: Saddle stitch bindings for mass produced documents will wear down over time and use on the paper.

Limited number of pages: The nature of the saddle stitch limits the number of pages that can be included due to the spine fold in the binding material.

Low quality appearance:While a brochure may look stunning, saddle stitch binding will keep it looking like a brochure or magazine. It is designed to be a less expensive binding and is often used for time sensitive materials.